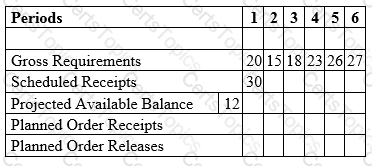

The question below is based on the following distribution requirements plan:

Lead time is 1 week, lot size is 30, and safety stock is 0. Planned order releases would occur in which of the following sequences?

Which of the following factors should be considered when evaluating a master production schedule change?

Which of the following items is required for making realistic customer promises?

A firm uses the level production planning approach to produce a product family to stock. Senior management has requested that the finished-goods inventory for the product family be reduced by 18% over the sales and operations planning horizon. Which of the following statements best describes the relationship between total demand and total production required for the product family over the planning horizon?